Hi Danny,

Firstly, why would you have gauges as assets unless there is some specific business reason?

Typically, a gauge is a non-maintainable instrument or, at best, something that doesn't need tracking. Therefore, you have a meter that represents a gauge.

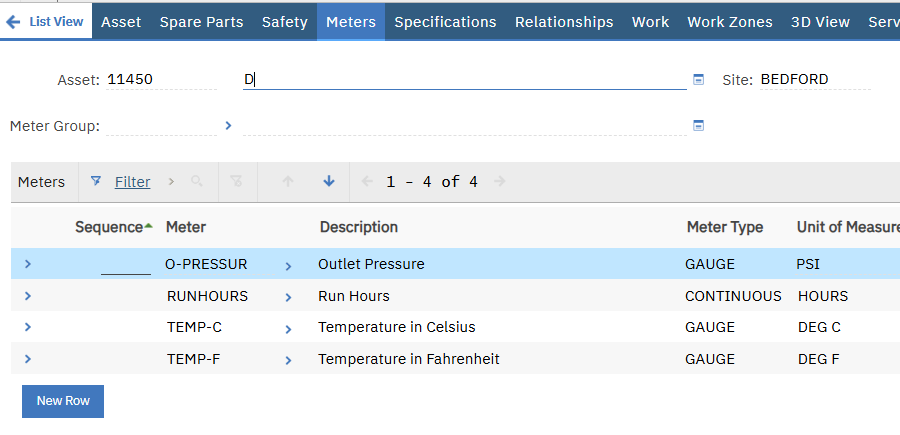

You can have as many meters as there are gauges, and each can also be added to the Condition Monitoring application.

Next, why are you changing out a gauge frequently? This would assume that you should look at the context of why that gauge is breaking so much and put into place something that would permanently fix or reduce the frequency of the occurrence. You could look at:

- The operating context

- The suitability of the gauge for its intended purpose

- The inspection routine

So, if a gauge is broken, how was this detected?

- By inspection

- By indirect consequence

- By direct consequences

So, let's examine the Condition Monitoring application. A CM point represents a meter on an asset where it has been identified that the gauge operates within a defined upper and lower boundary, or a characteristic that can usually be observed. In either case, it relies on a meter reading being taken and recorded.

How are you taking the reading (this is also aligned with how do you know that it's broken)?

- Direct

- Operator walking around and noting the reading

- Indirect

- A SCADA system receives a signal from the meter

As a matter of course, at some stage, the reading or lack thereof (zero reading) will breach the CM point. At some time later, when the MeasurePoint Cron Task does its sweep, the out-of-condition is located and a work order is generated, this will be either via the generation or a PM or using a JP on the work order. It does not matter which, as the intent should be to have a task that will involve someone in maintenance to:

- Be sent to inspect and report, raising a follow-up work order for the repair/replacement by someone else or to do it straight away.

- Be sent with a new/refurbished gauge to change out the gauge, with the broken one sent to the scrap or refurbishment

So, let's go back to your question "... I'm not sure I would get notified of the replacement..."

When would you like to know that it's broken?

- At the point that the out of tolerance occurred.

- When the work order was raised?

- When someone completed the work order?

- When someone issued a replacement gauge?

How would you like to know?

- Email

- Start center result set

- Workflow

Why do you need to know? Surely, it's up to maintenance to do the work.

What is it that you need to know?

Ultimately, why as the Maximo Admin are you taking the action when instead it "should" really be done through engineering or maintenance? I'm not a fan of giving the admin work that they should not be doing. In other words, we set up the system, train the users, and occasionally check that it's working as designed.

Now, let's examine the option of having a meter as an asset. Yes, this is valid, though not essential, as both the meter and the asset have the option to have a device ID assigned. The core difference is that now you have to have a child asset with the meter. If that meter is broken, you now have to do an asset swap, moving the broken one to a repair or salvage location and ensuring that the new one has a CM point assigned. Is this when you want to know that it's broken?

Ultimately, you inquired about "ideas that would require the least amount of paperwork and updating by a Maximo admin."

- Assign the meter to the asset

- Create a CM Point for the meter (NB: Do this first; you can skip #1 as Maximo does this for you)

- Ensure that the MeasurePointWoGenCronTask and the Organization are configured

- Record the meter readings

- Let Maximo generate the work orders (tracks that the gauge is broken)

- Issue the non-rotating gauge (tells us you installed a new one)

- Complete the work order and failure report (failure report tells us if you reset or replaced via the remedy code)

As we have been talking solely about gauge or characteristic meters, you do not need or rather cannot use, the reset/replace meter function, as that is for continuous meters.

Let me know what you think, especially if this has helped or if you need further clarification.

------------------------------

Craig Kokay

Principal Consultant

COSOL

email:

craig.kokay@cosol.global#IBMChampion

------------------------------

Original Message:

Sent: 09-11-2025 11:34

From: Danny Richardson

Subject: Multiple Condition Monitoring Points for Single Asset

Hello all, I was looking for ideas on how to manage an asset that is needing multiple meters and condition based monitoring points?

For example, if I have an asset that has multiple gauges that need to be recorded and if any of them are out of tolerance they generate their own work order.

I know that I could assign each gauge an asset number but they change them out frequently or if it breaks I'm not sure I would get notified of the replacement. I thought maybe rotating asset in this case.

But I am looking for ideas that would require the least amount of paperwork and updating by a Maximo admin.

Thank you in advance for any suggestions.

#Administration

#Assets

#Customizations

#EndUser

#EverythingMaximo

#MaximoApplicationSuite

#WorkManagement

------------------------------

Danny Richardson

Maximo Administrator Manager

Technimark LLC

------------------------------